Revolutionize Your CNC Manufacturing with NVIDIA Omniverse

NVIDIA Omniverse: The New Frontier for CNC Manufacturers and Industrial Innovators

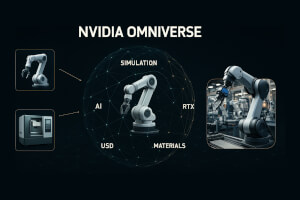

In the ever-evolving world of CNC manufacturing, embracing innovative technologies is key to staying competitive. Enter NVIDIA Omniverse™ — a groundbreaking platform that merges 3D simulation and AI to revolutionize industrial processes.

What Is NVIDIA Omniverse?

Imagine a collaborative operating system for industrial simulation. NVIDIA Omniverse is precisely that, bringing together SDKs, APIs, and microservices to create realistic, interactive 3D worlds. For CNC professionals, this means:

- Simulating entire production floors and workflows.

- Testing and optimizing part programs and toolpaths without interruptions.

- Building AI-driven digital twins that leverage real-time machine data.

- Integrating CAD/CAM, ERP, and MES systems into a unified visual platform.

How NVIDIA Omniverse Transforms CNC Manufacturing

1. Simulate Before You Fabricate

With Omniverse, you can visualize new programs virtually, allowing engineers to identify potential tool collisions and verify setups — all before actual production begins.

2. Connect Machines, Teams, and Data Silos

Omniverse promotes collaboration across departments, linking design engineers, programmers, and floor operators via live data streaming and USD-based interoperability.

3. Train AI With Synthetic Data

By using synthetic data generation, Omniverse enhances AI training for better defect detection and predictive maintenance, optimizing CNC workflows.

4. Build and Scale Digital Twins

Digital twins in Omniverse simulate entire factories, forecasting the impacts of process changes on cycle times and energy consumption to inform data-driven decisions.

Getting Started with NVIDIA Omniverse

Build: Develop on OpenUSD + RTX

Utilize the Omniverse Kit SDK for creating realistic 3D simulations and CNC training environments with superior rendering capabilities.

Deploy: Scale With Modular Microservices

Convert projects into containerized microservices with Omniverse Services, enabling local and cloud-based deployment for extensive collaboration.

Stream: Design and Simulate in the Cloud

Access real-time applications via Omniverse on DGX Cloud and major cloud services to facilitate global collaboration and process reviews.

Why CNC Manufacturers Should Care

For companies advancing towards Industry 4.0, Omniverse is crucial in bridging the digital and physical realms, offering benefits such as:

- Reduced setup errors and scrap rates.

- Enhanced workflow efficiency and machine uptime.

- Safe testing of process changes prior to implementation.

NVIDIA Omniverse is not just a tool but a foundation for smarter, more efficient manufacturing.

The Future of CNC Is Simulated

From CAD to cutting, Omniverse transforms ideas into a digital reality, enabling faster, smarter, and more sustainable manufacturing processes. It’s a pivotal gateway for those looking to optimize workflows and embrace the AI-powered factory of the future.

Learn more at NVIDIA Omniverse for Developers and discover how CNCmachines.com can facilitate your journey towards improved machine uptime and performance.