From Breakdowns to Breakthroughs: How Smart CMMS Tools Are Keeping CNC Machines Running Longer

From Breakdowns to Breakthroughs: How Smart CMMS Tools Are Keeping CNC Machines Running Longer

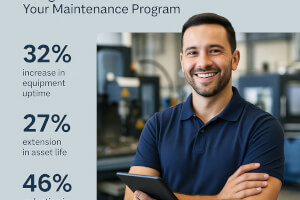

Modern maintenance technology is helping manufacturers boost uptime, cut costs, and build resilience—without hiring more people or buying new equipment.

The Hidden Cost of Downtime

In every machine shop, there’s one number that truly matters: spindle uptime.

When a machine goes down, production halts, delivery schedules slip, and margins shrink. Whether it’s a broken spindle, missed lubrication cycle, or a late work order, downtime doesn’t just cost money—it disrupts the rhythm of your entire operation.

At CNCmachines.com, we see it every day. Shops are under pressure to do more with less—fewer technicians, tighter budgets, and limited time—while still meeting customer demands. But the best shops aren’t working harder. They’re working smarter, using technology like modern CMMS (Computerized Maintenance Management Systems) and our own T.O.M. (Time on Machines) intelligence platform to build real-time reliability into every layer of production.

The Reality: Firefighting Is Expensive

For many CNC operations, maintenance still happens reactively. A spindle overheats, an axis motor fails, or coolant runs dry—and suddenly, the team scrambles to get it fixed.

Without visibility, the cycle repeats: unplanned downtime, rushed repairs, delayed jobs, and lost trust.

But forward-thinking teams are breaking that cycle by digitizing maintenance and turning reactive chaos into proactive control.

Modern CMMS: The Smart Backbone of CNC Reliability

A CMMS is no longer just a maintenance log—it’s a digital command center for uptime.

Modern systems help machine shops track, schedule, and predict maintenance across entire fleets of CNC mills, lathes, and automation cells. They bridge the gap between human technicians and machine data, helping lean teams do more with what they already have.

Here’s how top-performing shops are using CMMS tools today:

| Challenge | Old Way | Smart Way |

|---|---|---|

| Tracking maintenance | Paper, spreadsheets, memory | Mobile-first CMMS with alerts and scheduling |

| Work orders | Written after a breakdown | QR-code work orders triggered by machine data |

| Asset visibility | Manual checks, scattered notes | Real-time data via T.O.M. dashboards |

| Staff alignment | Verbal updates | Automated mobile notifications and reports |

The result: less downtime, fewer surprises, and higher ROI on every spindle hour.

QR Codes Meet CNC Machines

Imagine walking up to your Haas VF-2SS or Okuma LB3000EX and scanning a small QR code. Instantly, your screen displays:

- The machine’s full service history.

- Active maintenance tasks.

- Parts inventory and drawings.

- Last spindle inspection report.

Technicians can log service notes, attach photos, close work orders, and trigger follow-ups—all from their phone or tablet.

It’s fast, traceable, and fully integrated into your T.O.M. Time on Machines dashboard, giving managers and owners a live feed of every maintenance action across the shop floor.

Preventive Maintenance, Powered by Real-Time Data

Preventive maintenance (PM) is nothing new—but how it’s managed has changed entirely.

When paired with CMMS data and T.O.M.’s real-time monitoring, shops can move beyond static schedules and start maintaining based on actual spindle usage, cycle counts, and performance data.

For example:

- A spindle bearing approaching its vibration threshold automatically creates a PM work order.

- A coolant level sensor triggers a technician alert before tool failure occurs.

- Machine utilization data adjusts maintenance frequency dynamically.

Instead of guessing when to service, you know exactly when and why.

“Our shop used to spend half its week chasing machine issues,” says one Florida-based aerospace supplier using CNCmachines.com data tools. “Now we’re preventing them before they start—and we haven’t missed a ship date in six months.”

Mobile-First Maintenance: Workflows That Move With You

Today’s maintenance teams aren’t sitting behind desks—they’re walking the floor.

That’s why mobile CMMS platforms are changing how machine shops operate. With mobile-first systems, technicians can:

- Receive alerts directly from T.O.M. when a spindle’s runtime threshold is hit.

- Access drawings, service notes, and maintenance history on any device.

- Close out work orders with photos and voice notes on the spot.

- Automatically sync updates to management dashboards.

No more lost paperwork, delayed approvals, or waiting until the end of the shift to report an issue. Everything happens in real time, from the CNC bay to the cloud.

Proof in the Numbers: CMMS + T.O.M. Impact

| Metric | Before Digitization | After CMMS + T.O.M. Integration | Improvement |

|---|---|---|---|

| Average CNC Uptime | 79% | 94% | +15% |

| Reactive Maintenance Hours | 62% | 25% | -37% |

| Work Order Completion Time | 2.5 days | < 1 day | -60% |

| Mean Time Between Failures (MTBF) | 105 hrs | 190 hrs | +80% |

By combining CMMS automation with T.O.M. analytics, even small shops can see big results—without adding headcount or buying new equipment.

How to Get Started

Building a smart maintenance strategy doesn’t require a six-figure software project. It just takes a clear plan and consistent execution.

Here’s your step-by-step blueprint:

- Start with visibility – Audit every CNC machine, from uptime history to common failure points.

- Digitize your PMs – Turn manual maintenance checklists into scheduled digital tasks.

- Tag your assets – Apply QR codes to your most critical machines for instant data access.

- Adopt mobile workflows – Give your technicians the tools to manage maintenance on the go.

- Connect it all with T.O.M. – Use Time on Machines to track uptime, behavior, and trends in real time.

Within weeks, you’ll have a clear, data-driven picture of machine health—and a maintenance culture built on prevention, not reaction.

The Future: Connected Machines, Connected Teams

The manufacturing floor of the future isn’t just automated—it’s intelligent and interconnected.

Every CNC machine, technician, and manager shares a single source of truth: live operational data. Failures are predicted. Maintenance is proactive. Uptime is optimized.

With CNCmachines.com and T.O.M., you can transform maintenance from a cost center into a competitive advantage—turning downtime into opportunity and chaos into control.